Custom Compression Springs

Compression springs are linear load resistant springs that are commonly used as an efficient method of storing energy. Argo Spring Manufacturing’s versatile equipment is capable of producing custom compression springs of variable pitch and ground within 1°.

End Types Include:

- Plain: Open or closed

- Squared: most commonly designed with closed ends to provide uniform force distribution

- Ground: provides flat planes and stability

- Ground/Square: utilized for applications that require small load/rate tolerances and used for its durable and non-buckling characteristics.

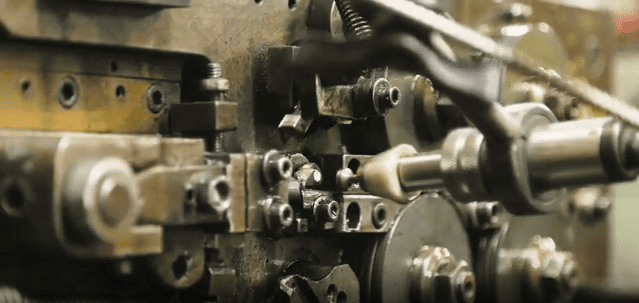

Examples of Our Work

Specifications

- Wire Diameter

-

0.002″ to 0.625″

- Spring Shape

-

Barrel

Conical

Cylindrical

Taper

- Wire Shape

-

Rectangular

Round

Square

Stranded

Trapezoid

- Material

-

Carbon Steel

Music wire

Hard Drawn

Oil-tempered

17-7 Stainless Steel

316 Stainless Steel

302/304 Stainless Steel

Titanium

Inconel

Hastelloy

Monel

Molybdenum

Exotic Material

Chrome Palladium

Chrome Silicon

- Coating

-

Black Oxide

Powder Coating (any color)

- Plating

-

Zinc

Cadmium

Tin

Silver

Gold

All Precious Metals

Process Information

- Stress Relief

-

All springs are stress relieved per material specification.

- Quality Control

-

- ISO 9001:2000

- MIL-1-45208A certified

- Mandatory 1st Article check process

- When requested, the 1st Article check can be approved by the customer.

- Statistical Process Control measures

- Optical Comparators

- Load Testers

- Rockwell testing

- Engineering Services

-

Based on application requirements, the Engineering Department advises and creates designs for any custom product.

- Industries

-

- Aerospace

- Automotive/Trucking

- Agriculture

- Consumer Products

- Medical

- Government and Defense

- Energy & Utilities